Our Parent Company is M/s.INDUSTRIAL ENGINEERS(INDIA) Group of Company www.industrialengineersindia.com

Phone: +91 98409 88641

Services

TYPES OF WORKS

- All Type of HT/LT-AC Motors (up-to 1500KW)

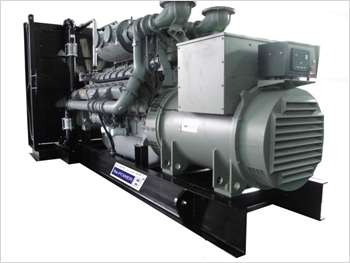

- Generators / Alternators (up-to 2000KVA)

- DC Motors (up-to 500 Frame)

- Wind Induction Generators (up-to 1.2MW)

- HT/LT Transformers (up-to 2000KVA)

- AC/DC Servo Motors

- Eddy Current Transformers & Motors

- Vibrator Motors

- Synchronous Generator Re-winding & Repairs

- Rewinding of synchronous & Non-synchronous Field / Rotor Coils

- Rewinding of Servo Transformers

- Auto Transformers

ALL TYPE AC/DC ELECTRIC MOTOR REWINDING, RECONDITIONING, REDESIGN AND REPAIRS

- All sizes and HP, 110 -415 Volts AC motors, 110-600 Volts DC motors.

- Rebuilding of AC and DC electric motors from small to 1500HP (1.5KV)

- Armatures Rewinding / wound rotors repairs

- Dynamic Rotor Balancing (Synchronous/Non Synchronous)

- Vacuum Pressure Impregnation

- Generator (Stator/Rotor) Rewinding and Repair

- Exciter stator and rotor rewinding

MECHANICAL SERVICES

- Fabrication and replacement of shaft, end covers and bearing Housings.

- Trouble shooting & resolving vibration, noise & overheating problems.

- Casting of DE & NDE Shields, Bearing Housings, Couplings and Fans Duly Machined as per O.E.M. specifications.

- Complete overhauling of Motors, Generators & Transformers.

- Annual Rate Contract for maintenance of Motors & Alternators.

We have covered following activities

- Rewinding with Resin rich Insulation

- Rewinding with Resin poor Insulation (VPI)

- Manufacturing and supply of coils

- Re-insulate Edge wound Synchronous Coils

- Reboring/ Re-casing of all types of Rotors

- Synchronous Rotor Impedance Testing

- Insulation System Designs and Upgrades

- Re designing to customer needs-Pole changing

- Stator core Restacking and Recoating

- Re designing to customer needs-Frequency conversion

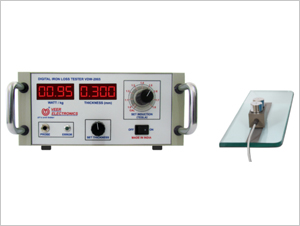

Testing Equipments

Electrical Testing of Motor Components and Equipment

- Functional Test

- Hi-pot Testing

- Core Loss (Ring Flux) Testing

- Megger Testing

- Dynamic Rotor Balancing

- Surge Testing / Surge Comparison Testing of 3-Phase Windings

- Bar to Bar Check of Armatures

- Testing of Die-Cast Induction Type Rotors for Open Bars

- Milliohm Resistance Testing